|

Ningbo SUP Bearing Co., Ltd.

|

205TDIS727 TORRINGTON BEARING

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Used for rolling mill bearing arrangements,For roll neck bearing arrangements which are subjected to high speeds or heavy loads

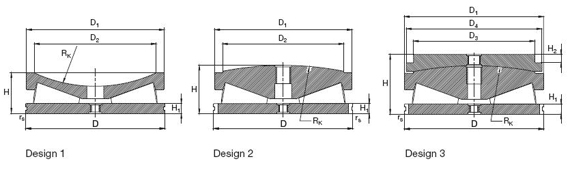

Bearings of the TDI configuration

Bearings of this configuration have a double row inner ring with two roller and cage assemblies (double cone) and two outer rings (cups). The two rows of rollers are arranged face-to-face. Normally an intermediate ring is arranged between the two outer rings. This ring is dimensioned so that a certain axial clearance or preload will be obtained.

The bearings are eminently suitable for locating bearing arrangements and are produced by SUP BEARING with a cylindrical bore; some sizes are also produced with a tapered bore. For bearing arrangements where the bearings are to be mounted with a loose fit on the shaft or journal, special designs are supplied by SUP BEARING. To counteract the disadvantage of a loose fit on the shaft – the inner ring turns on its seat, which can cause damage to the bearing and the seat – these special bearings have a helical groove in the bore and/or lubrication grooves in the side faces of the bearing rings . These grooves enable lubricant to be efficiently supplied to the sliding contact surfaces.

Bearings having a large contact angle are a special design of the TDI configuration. These bearings have a particularly high axial load carrying capacity and are used primarily as thrust bearings in rolling mill applications. As they are mounted with a loose fit on the roll neck and only subjected to purely axial load, the inner ring has one or more notches in one or both side faces to permit it to be secured and prevent it from turning on its seat. Depending on the application the bearings are supplied with or without an intermediate ring between the two outer rings. They can also be supplied as self-retaining units with a retention sleeve over the outer rings.

These self-retaining bearing units with retention sleeve are characterised by high load carrying capacity and simple handling compared with conventional bearings. The outer rings are integrated in the sleeve. The deformation of the outer rings normally resulting from heavy axial loads is considerably reduced by this means and as a consequence the stress distribution in the rolling contacts is more favourable leading to longer life. The axial internal clearance is determined by the sleeve. Preloading by means of springs is not needed. The arrangement design is simplified and thus more economic and mounting is also easier.

Size range: ID 25.400 mm to 1200.150 mm (1.000 in. to 47.2500 in.)

OD 30.480 mm to 2460.000 mm (1.2000 in. to 96.8504 in.)

Design Attributes

Double cone and two single cups, with or without a cup spacer.

Furnished as a matched assembly.

Cups ground to fit.

Applications

Gear reduction units

Cranes

Calendar rolls

Industrial machinery

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)