You are here: home > Taper roller bearings > double rows tapered roller bearing > M 238840/810D CHINA

M 238840/810D CHINA

| Payment Terms: | T/T,L/C |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

M 238840/810D

Production Capacity:

100

Delivery Date:

60~70

Means of Transport:

by sea ,by airplane

Packing:

smoked-free wooden box

Brand Name:

SUP OR NATURAL

Used for rolling mill bearing arrangements,For roll neck bearing arrangements which are subjected to high speeds or heavy loads

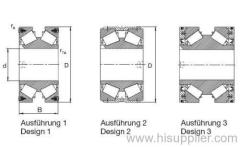

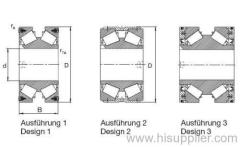

Bearings of the TDO configuration

Bearings of the TDO configuration have one double row outer ring, or cup, and two inner rings with roller and cage assembly, or cones. Normally these bearings have an intermediate ring between the two cones. They are thus ready-to-mount units as adjustment of the axial clearance or preload has already been made at the production stage. In these bearings the cones are arranged back-to-back so that the load lines diverge towards the bearing axis. By virtue of this the bearings enable relatively stiff arrangements to be made which can accommodate considerable tilting moments.

These arrangements may be either locating or non-locating. For non-locating arrangements the axial displacement must take place between the outer ring and the housing bore. Those bearings having a blind hole or locating slots in the outer ring are particularly suitable for mounting with a loose fit in the housing as a cylindrical pin which engages the hole or slot can be used to prevent the outer ring from turning in its seat. To enable axial displacement of these bearings in the housing it is recommended that the pin should have a smaller diameter than the hole.

SUP BEARING double row tapered roller bearings of the TDO configuration are generally produced in the designs described in the following. Basically these designs differ in cage design or whether provision is made for relubrication or an intermediate ring is positioned between the inner rings.

The configuration of the TDO provides a wide effective bearing spread, making it ideal for applications in which overturning moments are a significant load component. TDO bearings can be used in fixed positions or allowed to float in the housing bore.

Size range:

ID 25.400 mm to 1200.150 mm (1.0000 in. to 47.2500 in.)

OD 30.480 mm to 2460.000 mm (1.2000 in. to 96.8504 in.)

Applications:Heavy-duty gear drives ,Various industrial configurations

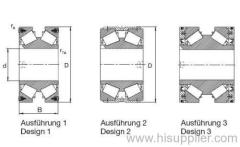

Bearings of the TDO configuration

Bearings of the TDO configuration have one double row outer ring, or cup, and two inner rings with roller and cage assembly, or cones. Normally these bearings have an intermediate ring between the two cones. They are thus ready-to-mount units as adjustment of the axial clearance or preload has already been made at the production stage. In these bearings the cones are arranged back-to-back so that the load lines diverge towards the bearing axis. By virtue of this the bearings enable relatively stiff arrangements to be made which can accommodate considerable tilting moments.

These arrangements may be either locating or non-locating. For non-locating arrangements the axial displacement must take place between the outer ring and the housing bore. Those bearings having a blind hole or locating slots in the outer ring are particularly suitable for mounting with a loose fit in the housing as a cylindrical pin which engages the hole or slot can be used to prevent the outer ring from turning in its seat. To enable axial displacement of these bearings in the housing it is recommended that the pin should have a smaller diameter than the hole.

SUP BEARING double row tapered roller bearings of the TDO configuration are generally produced in the designs described in the following. Basically these designs differ in cage design or whether provision is made for relubrication or an intermediate ring is positioned between the inner rings.

The configuration of the TDO provides a wide effective bearing spread, making it ideal for applications in which overturning moments are a significant load component. TDO bearings can be used in fixed positions or allowed to float in the housing bore.

Size range:

ID 25.400 mm to 1200.150 mm (1.0000 in. to 47.2500 in.)

OD 30.480 mm to 2460.000 mm (1.2000 in. to 96.8504 in.)

Applications:Heavy-duty gear drives ,Various industrial configurations

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Find more related products in following catalogs on Hisupplier.com

Related Products

.jpg)

Company Info

Ningbo SUP Bearing Co., Ltd. [China (Mainland)]

Business Type:Manufacturer, Trading Company, Distributor/Wholesaler, Service

City: Ningbo

Province/State: Zhejiang

Country/Region: China (Mainland)

You May Like:

Product (3941)

- Bearings for Oil Production & Drilling (14)

- Bearings for Concrete Mixer Gear Reducer (5)

- Spherical Roller Bearings (2)

- Taper roller bearings (2510)

- Slewing ring (42)

- Deep groove ball bearings (1)

- Cylindrical roller bearings (1043)

- Spherical roller thrust bearings (3)

- Taper roller thrust bearings (52)

- Cylindrical roller thrust bearings (204)

- Full complement cylindrical roller bearings (3)

- Auto bearings (9)

- Spherical plain bearings and rod ends (4)

- Angular contact ball bearings (3)

- Self-aligning ball bearings (1)

- Needle roller bearings (12)

- Miniature bearings (6)

- Bearing housings (6)

- Bearing units (5)

- Thrust roller bearings (3)

- Roller Bearings (11)

- Ball Bearings (2)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)